case study

Transforming Design, Safety, Production & Customer-Experience in the Automotive Sector

For heavy-manufacturing sectors such as automotive, the convergence of AR/VR/MR + IIoT + AI means faster design-to-production cycles, reduced risk, improved safety compliance, and measurable emissions & energy savings.

* Eliminate multiple physical prototypes → reduce R&D time by up to 30%.

* Engage cross-functional teams (design, manufacturing, service) via immersive walkthroughs and “what-if” scenario testing.

*Why this matters for automotive: In a plant with 100,000 sq m assembly floor, a 30 % reduction in prototype cycles can save millions of dollars and speed time-to-market.

Frontline operators, service technicians and on-site inspectors use camera-based AR overlays on mobile/tablet devices to instantly access contextual information, guided workflows and asset-specific instructions:

Technician points a tablet/mobile at the equipment and sees AR overlays of labels, components, SOP steps, and part-level highlights.

* AR-driven safety checks enable instant hazard zone identification, PPE verification prompts, and lockout-tagout confirmation.

Service teams, maintenance engineers and field technicians benefit from MR overlays that combine real-world equipment + live digital guidance:

* Service technician wearing AR-glasses sees component breakdown, digital instructions, live remote expert view.

In the automotive sales and marketing funnel, immersive experiences build preference, accelerate purchase decisions and enhance brand perception:

* For B2B (fleet/industrial vehicles) you can simulate vehicle installation, service‐dock impact, body configuration and demonstrate virtually.

With the Wistwin digital-twin platform you build a live virtual replica of your entire production line — robots, conveyors, painting booth, battery module assembly, QA stations, etc. Key value drivers:

*Real-time performance monitoring & analytics: capture IIoT data, apply AI/ML to identify inefficiencies.

*Emulation of scenarios: test line changes, layout shifts, new models without disrupting actual production.

* Scalable across manufacturing sites and geographies.

Benefits

Why Global Brands Choose VB Metaverse

Our Values

A decade of global risk expertise now powering advanced, specialised solutions for the automotive sector.

Sustainability, Smart Factory & Carbon-Footprint-Reduction

With Wistwin you not only improve efficiency — you reduce environmental impact.

Why Choose VB Group for Your Automotive Immersive & Digital-Twin Journey

*Proven track-record in industrial twinning, arc-flash risk, piping/gas-line digitisation — domain expertise that translates into automotive.

* End-to-end capabilities: From data-collection (VB Tantra) through digital-twin (Wistwin) to immersive training & customer experiences (Drona, 360Vista).

* Tailored for automotive/mobility sector: We understand the constraints of vehicle manufacturing, assembly, maintenance, service-ecosystems and safety regulations.

* Sustainability-first mindset: Built-in energy-monitoring, waste-reduction and ESG alignment.

Why this matters

*As the automotive industry pivots toward electrification, smart factories and sustainability, immersive technologies and digital twins are no longer optional — they're fundamental.

* Global “industrial metaverse” and digital-twin investment is expected to create up to US $5 trillion in value by 2030.

EHS & Safety Training — immersive, scalable, measurable

Safety is a top concern for every manufacturing leader, especially in high-risk operations (robotics, paint booths, EV battery assembly, high-voltage systems).

Our solution stack:

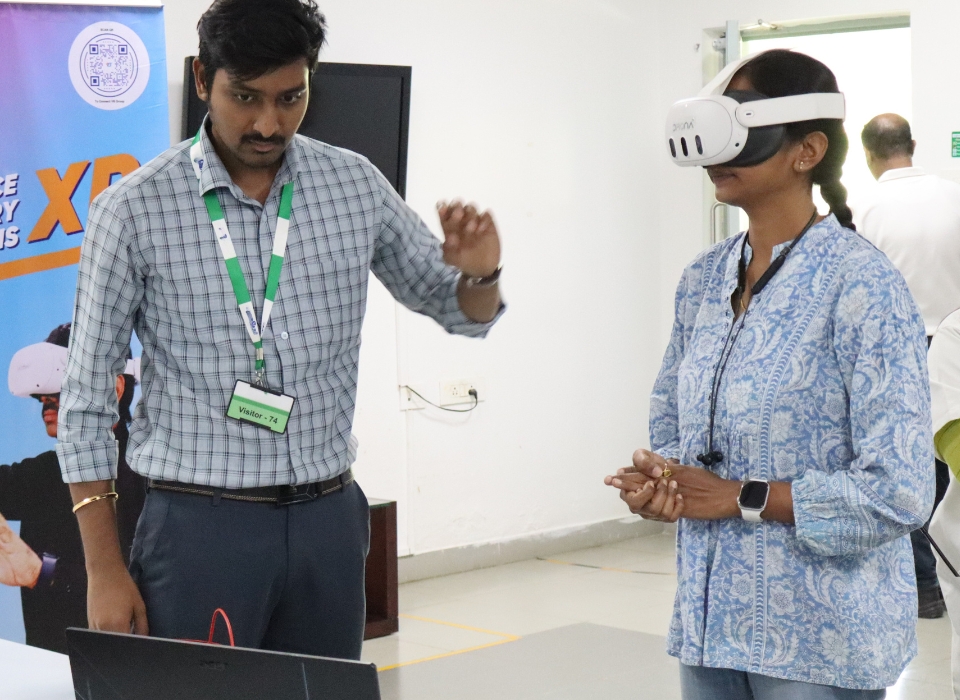

* Drona VR modules: hazard-simulation, emergency-response training, operator drills.

* MetWin MR: overlay digital instructions/holograms on the physical shop-floor or vehicle assembly line.

*Impact example: Deployment of our kiosk-based training (with interactive assessment and gate-pass generation) across 100+ plants has resulted in onboarding time cut by ~50% and improved compliance scores.

*For automotive lines: Introduce new high-voltage battery module line; train contractors and visitors in a virtual environment — no physical exposure, every scenario captured, analytics available.